THE ELASTOMERIC TUBE SWAGING PROCESS

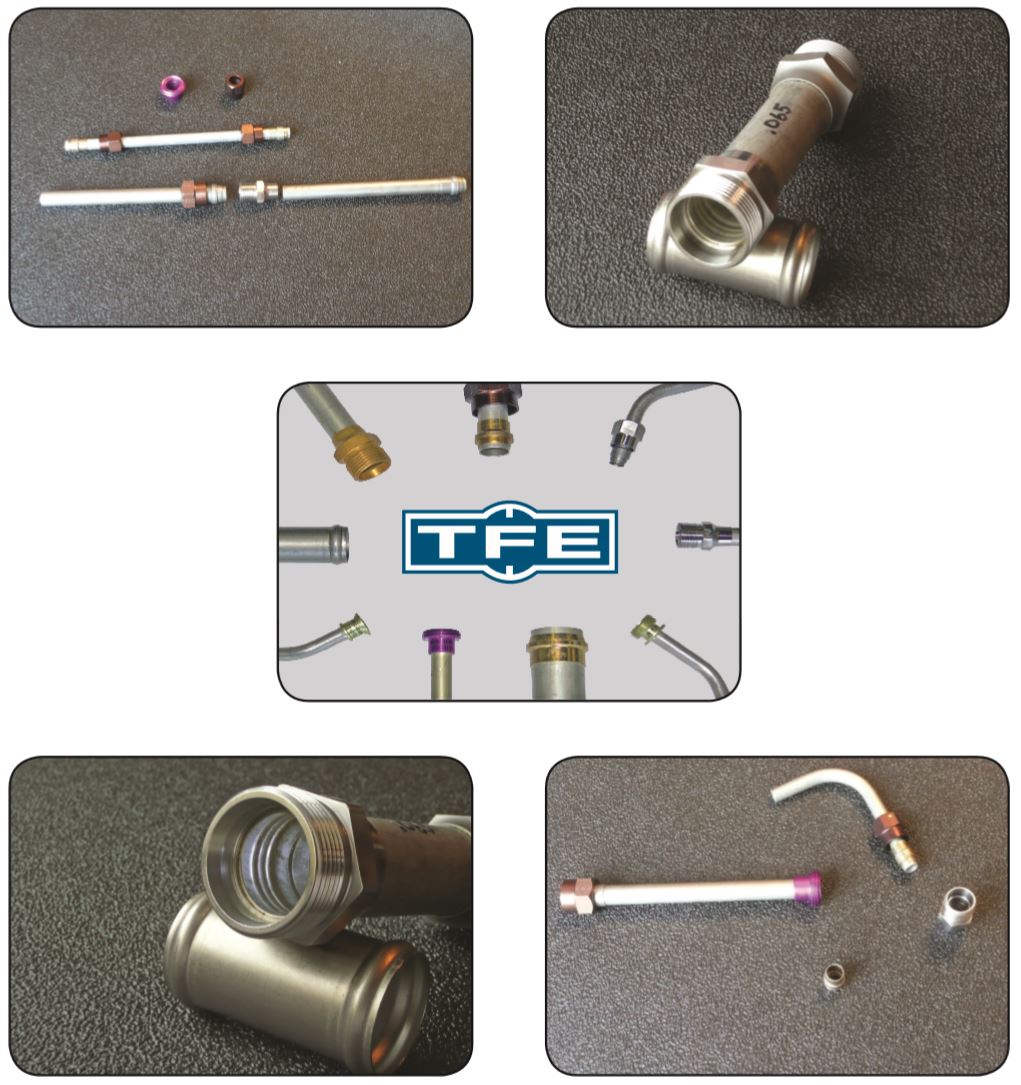

This process is widely used in the commercial and military aircraft industry to fabricate tubing assemblies for hydraulic, fuel, oxygen, and similar fluid distribution systems. Currently, elastomeric swaging is used to fabricate tubing assemblies for both low and high pressure fluid systems made from aluminum, steel, stainless steel alloys, and titanium. Elastomeric swaging of end fittings produces fluid tight connections without the loss of material strength associated with thermal joining methods such as brazing and welding. In addition, elastomeric swaging produces high quality mechanical tube fitting attachments without the wall thinning and local stress concentrations produced by mechanical roller swaging or the older bite type designs.

In addition to serving the aerospace industry, we are now introducing our internal elastomeric swage machines and support tooling to other industries. Swagers can be used in the construction of marine engines, automobiles, trucks, refrigeration, air conditioning, motorcycles, motor homes, construction equipment, and tractors.The process is a cold forming process which utilizes extremely high radial forces applied to the internal surfaces of a tubular member to displace the tubing into grooves in an external end fitting, or into a shaped die cavity to produce tube end forms such as beads. The internal swaging forces are produced by the controlled linear travel of a high strength drawbolt which compresses an elastomeric expander against a static retainer ring surrounding the drawbolt. During the swaging cycle, controlled compression of the elastomeric material forces the tube wall radially into internal circumferential grooves in the end fitting skirt, producing a strong, leak proof mechanical attachment. During forming, the tube end fitting is contained within a precision matching split die cavity to provide a reactionary force to the forming operation and prevent distortion of the fitting.

Elastomeric swaging is a very rapid, efficient, and practical tube end fitting attachment process that eliminates expensive post processing operations such as radiographic or ultrasonic inspection frequently required for welded and brazed connections

We manufacture all forming dies and swage tooling for each of our elastomeric tube swagers. Pricing for these items must be quoted based on customer requirements and quantity. Each swager is equipped to comply with all applicable safety standards as well as the electrical compatibility requested by the customer. An operation and safety training package is included with each swager purchased. A six month warranty on all parts and workmanship is included in the purchase price.

All swage machines are in compliance with the performance standards for product acceptance in the commercial aerospace industry. They are manufactured and tested in Arlington, Washington, USA.